-40%

7" 2-Axis Flame / Plasma Cutting Controller System With Torch Height Controller

$ 310.99

- Description

- Size Guide

Description

template2-Axis CNC cutting machine system SF-2100C Plasma flame cutting machine controller With HP105 Torch Height Controller + JYKB-100 24VDC Lifer

New

7" 2-Axis Flame / Plasma Cutting Controller System

Precautions for use:

1. After the package is opened, please check if the system is damaged during transportation. The contents listed on the packing list are consistent with the contents of the box.

2. This manual is applicable to the CNC system of SF-2100C-QG cutting machine produced by Beijing Star Peak Control Technology Co., Ltd.

3. Please check if the grid voltage is correct. An AC220V isolation transformer is used between the grid and the system to ensure reliable system operation and personnel safety.

4. The numerical control system requires the working environment temperature to be 0 °C ~ +40 °C, and the relative humidity is 0-85%.

Special protection is required if working in environments with high temperatures, high humidity and corrosive gases.

5. The wiring of each part of the CNC system should be correct and the ground wire should be in good contact.

6. The CNC system does not allow all the cable plugs on the rear of the chassis to be plugged and unplugged. As a result, the company refuses the warranty.

7. The line of the rear output port of the CNC system is not allowed to be short-circuited with other power lines; otherwise, the CNC will be burned.

8. In a high dust environment, the whole machine needs to be dustproof, and it is necessary to clean the dust regularly to ensure the cleaning of the CNC system.

9. The CNC system should be managed by a dedicated person and the operator should be trained.

10. It is not allowed to connect the AC/DC power supply used inside the CNC system to other appliances.

11. In case of problems, please contact us. Do not disassemble or modify the system yourself without being familiar with it.

12. Maintain the system and machine tool, perform routine maintenance and inspection every shift; perform secondary maintenance once a month; perform primary maintenance every six months.

13. The parameters set by the CNC system should be set strictly in accordance with the instructions in this manual or the supplementary instructions at the time of ordering; if the set parameters are outside the specified range, the CNC system will work abnormally or even be damaged.

14. The LCD screen of the system is fragile, and the LCD should be protected during use.

15. The technical specifications of this system are subject to change without prior notice.

16th. Note:

The USB port output power of the system is very small, and it can only be used by the U disk. It cannot be connected to other USB devices to prevent damage.

System functions

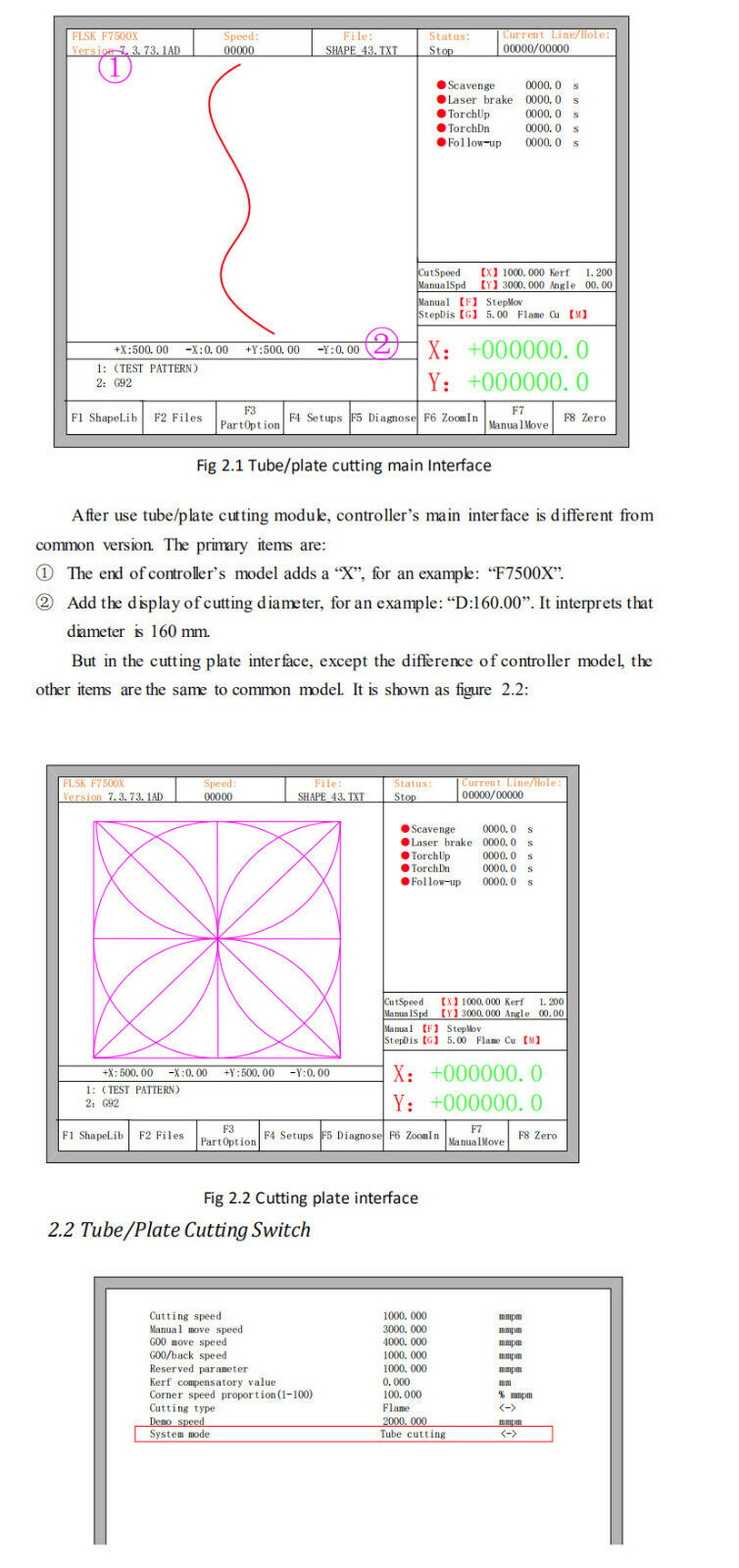

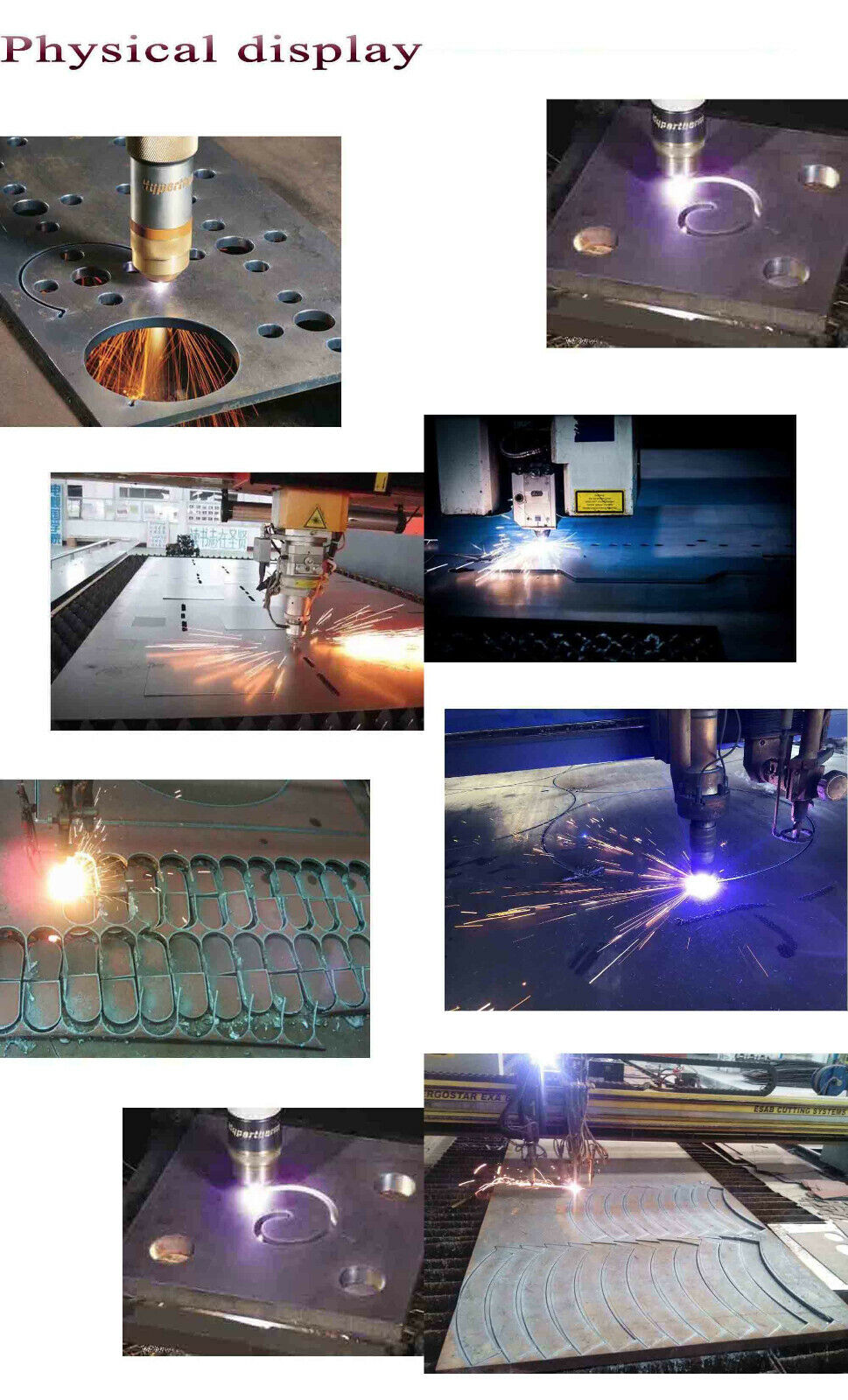

SF-2100C-QG cutting machine CNC system is suitable for all kinds of flame / plasma, high pressure water jet, laser cutting machine, widely used in metal processing, advertising, stone and other industries.

The system is highly reliable and has the ability to resist plasma interference, lightning strikes and surges.

Practical flame/plasma cutting process, automatic corner rotation control and height control control during plasma processing; remote operation with wireless remote control.

It has the function of kerf compensation, and whether the compensation in the program is reasonable, and the corresponding report is made for the user to choose;

Breakpoint recovery, automatic power-off recovery function, automatic memory breakpoints;

Arbitrary selection and selection of perforation point processing functions;

It has an epitaxial perforation function for thick plates and a bridging function for thin plates;

Back-off, selection, breakpoint recovery, optional perforation position and other functions, greatly facilitate the user's control;

Transfer cutting at any time;

It adopts a special small line segment processing function, which makes it easy to walk and can be widely used in metal cutting and advertising, wrought iron, etc.

A library of 24 graphics (expandable and customizable) containing common basic machining parts;

Fully compatible with StarCAM nesting software, compatible with IBE (Germany), FASTCAM and other mainstream nesting software;

Chinese and English operation interface conversion, dynamic graphic display, 1 to 8 times of graphic magnification, automatic tracking of moving points, U disk reading program and timely software upgrade.

1.2 Technical indicators

Processor:

using industrial grade ARM processing chip;

Display:

7-inch color LCD display;

InputOutput:

The system provides 16 optically isolated inputs and 16 optically isolated outputs.

Number of linkage axes:

2 axes, (can be driven by X-axis bilaterally or Y-axis bilaterally)

Maximum speed:

not less than 24 m / min;

Pulse equivalent:

flexible adjustment;

Storage space:

4G large user program storage capacity, processing procedures are not limited;

Chassis size:

298 × 202 × 65 (mm);

Working temperature:

0 ° C ~ +40 ° C; storage temperature : -40 ° C ~ +60 ° C ;

Function word definition:

N command segment number

G preparation function

M auxiliary function

T tool function (in this system is the flame width)

L cycle number, delay time

X X axis (diameter) absolute coordinates

Y Y axis absolute coordinates

I When the arc is machined, the center coordinate value is reduced by the X axis starting point value.

When the arc is machined, the center coordinate value is reduced by the Y axis starting point value.

R arc radius specification

H arc string height specification

A auxiliary variable

F machining speed specification for G01, G02, G03

parameter description.

Speed parameter

Starting speed, adjustment time and maximum speed limit of each axis;

System Parameters

Electronic gear ratio of each axis, machine origin, reference point, backlash, line offset, soft positive/negative limit;

Flame cutting parameters

Ignition delay, preheating delay, cutting gun up/down delay, perforating torch up/down, piercing delay, etc.

Plasma parameter

Cutting gun positioning delay, M command for arcing, M command for arc breaking, arc pressure detection selection, positioning detection selection, piercing delay;

control parameter

Flame/plasma selection, processing speed limit, edge perforation selection, metric/imperial selection, etc.

Storage Function

The modified parameters are stored in the parameter area.

Press the S key continuously to select the external manual control button to select whether it is valid or invalid.

Software upgrade operation instructions (software free upgrade)

First, the operation steps

1. Format the USB flash drive in FAT or FAT32 format. It is recommended to use the FAT format.

2. Copy the upgrade file into the USB flash drive. The name of the upgrade file must be STARTCNC.EXE.

3. Press and hold the arrow button on the left side of the USB port to power on the system, power up the system, and plug the USB disk into the USB port of the system.

4. The system automatically enters the upgrade interface, press the F1 button on the panel (ie, the corresponding button for the upgrade);

5. If the upgrade is normal, after the upgrade is complete, the system will display “Upgrade Successful!”.

6. Turn off the power, pull out the USB flash drive, and the upgrade process is complete.

Second, the exception process of the upgrade process

Check that the name of the upgrade file must be STARTCNC.EXE.

If this factor has been eliminated, you can re-operate according to the operation steps. If multiple attempts still fail, you can call customer service.

HP105 Torch Height Controller

Description:

- HP105 plasma arc voltage height controller is equipped with constant current plasma. During cutting courses, the current always equals the given current. And the cutting arc voltage will be changed with the fixed speed being the height of torch changing.

- When the distance gets farther,the arc voltage increases; On the opposite, the arc voltage will decrease. HP105 plasma arc voltage height controller will inspect the voltage change, then control the distance between cutting torch and material via the lift motor. So that the arc voltage is fixed, the same is the height of cutting torch. Generally, the instruction will list all the cutting parameters for some type of plasma.

- The user can refer to these parameters. Adjust the voltage in the arc voltage height controller to match the selected current. The torch height will keep constant under regular speed. In fact, the user should set the arc voltage according to the height of the cutting torch. In the status of automation, the arc voltage higher, then the height of the cutting torch higher.

Specification:

Working voltage: DC24±10%,50Hz/60Hz,Please prepare an isolated power, do not share with others such as an electronic valve. Especial Pay more attention the DC 24V

Lift motor: DC24V DC motor

Drive mode: PWM

Output current:1A-4A.

Working temperature: Height controller -10∽60℃

IHS style: Switch inspecting IHS (suitable for all plasma

both above-water and under-water cutting), Plasma Shield

Protector IHS (suitable for above-water cutting’s touch

leading arc voltage plasma)

l Running transfer: Alternative Arc transfer and pierce transfer

l Divided voltage ratio:100:1

l Accuracy: ±1V∽±5V,adjustable

l Outer Dimension: Length X Width X Height:

225mmX50mmX80mm

Weight: 0.8kg

Protection class: IP64, to prevent dust from entering.

Installation connector: 2-pin, 4-pin, 5-pin, DB-9 core

Installation position: Keep away from heat, air convection good place.

Function Description:

LCD: display the working status and parameters.

Manual: Auto / Manual mode selection increase, alternating work.

Arc test: standby press, arcing into the test mode.When arcing test, press to return to standby mode.

Menu: In standby, mode press to enter the parameter setting mode.

When the parameter setting Press to return to standby.

Confirmation: parameter setting mode, confirm that the set parameters.

Rise/fall: In standby mode, manual lifting torch.When parameter sets, subtraction parameter values.

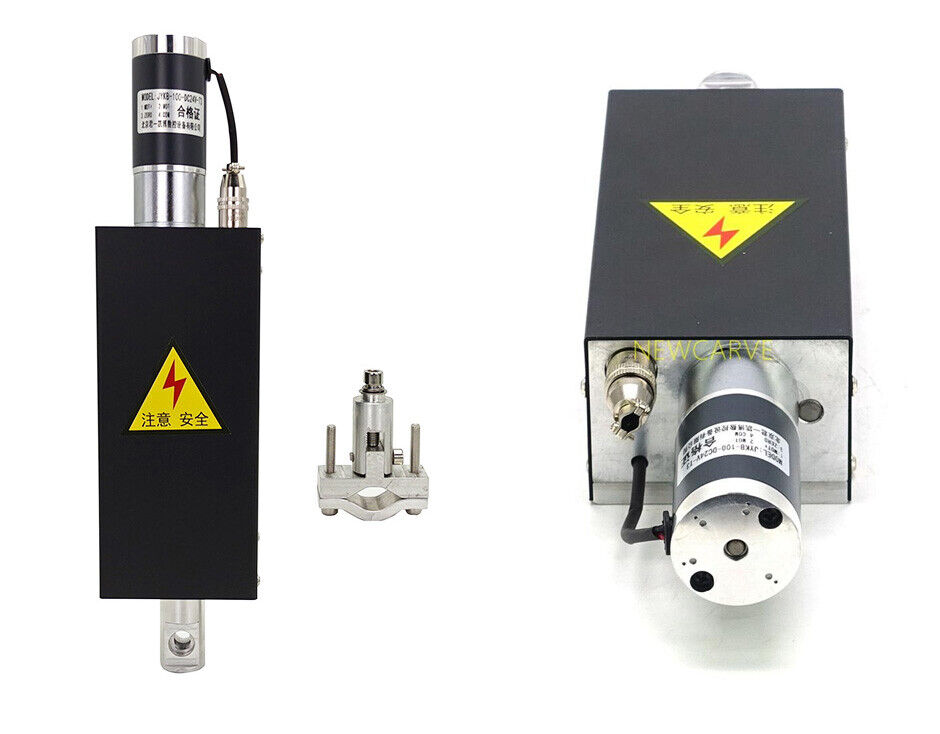

JYKB-100 24VDC Lifer

Application:

Portable/desktop light-duty CNC flame/plasma cutting machine.

Description:

1. This flame/plasma cutting machine Z-axis torch lifter is driven by DC gear motor to lift the torch up & down

2. The most important part of the device, which is to keep the machine's cutting accuracy and to support plasma arc positioning function, is equipped with NPN proximity switches

3. This lifter's mechanical movement part is made of Taiwan TBI ball screw, standard linear shaft(SFC) & linear slider on the ends; torch clamper/holder is made of bearing steel, and fastened by linear sliders, which is to ensure the lifter movement's stability & verticality

4. Convenient to install, work simple, improving the work efficiency

Air control plug definition:

1 foot --D +; (motor positive)

2 feet --D -; (motor negative)

3 feet --Zero; (positioning normally open output)

4 feet --COM; (positioning normally open output)

Note: Built-in limit (reverse diode)

Parameter:

1. T-304 stainless steel screw

2. Includes jig (torch range 12mm-38mm)

3. Lift inside a plasma arc positioning

4. Aluminum body, the upper and lower aluminum sheet thickness of 8mm, forming a processing center

5. Four-core plug

6. Colour: black spray housing

7. Working stroke: 100mm

8. Working voltage: DC24V

9. Bearing weight: 3 kg

10. Dimensions: length 320 * W 80 * H 60

11. Mounting Hole Size Length: the center distance between two holes 40mm

1.Your valid phone number is very necessary for the shipping, otherwise we can't guarantee that the package would safely arrives.

2. Any Customs tax applied to this package should be covered by buyers.

3.As has been stated on the eBay item description, Import duties, taxes and charges are not included in the item price and shipping charges. These charges be at the buyer responsibility. meanwhile the customs tax depend on the buyer local customs office.

What in Package:

1 x 2-Axis CNC cutting machine system SF-2100C

1 x HP105 Torch Height Controller

1 x JYKB-100 24VDC Lifer

Contact Us:

1. We have always been trying to provide the best service and reliable products for every customer, however, accident may happen sometimes, please contact us to resolve any issue before leaving a negative feedback.

2. Please contact us by "Ask a question".

Payment

1. Payment methods accepted :

Paypal

only

.

2. Payment must be received within 7 business days of auction closing.

Shipping

1. We ship your orders within 1-3 business days after the payment received.

2. Item shipped via Singapore Post or HongKong Post , It takes about 7-30 business days (USA,CA,AU,UK).others country 10-20 business days(Brzil,India,RU),Exact delivery time depends on postal process.

3. If you do not receive your item(s) by 30 business days,Please feel free to contact us via ebay mail system , we will try our very best to resolve any problems with you

Return Policy

1. Return is accepted within 30 days after the buyer's receiving the item.

2. If this item is defective upon receipt, customer has up to 14 days from date of receipt for exchange of a new one.

3. Unused/unopened merchandise will be fully credited.

Other Policies

We are not responsible for any custom duty or import tax.

If you need we write low price on shipping bill, pls leave message when you make payment .

All emails will be answered within 24 hours. If you do not receive our reply, please kindly re-sent your email and we will reply to you as soon as possible, Suggest send eBay message to us, That is easy to find .